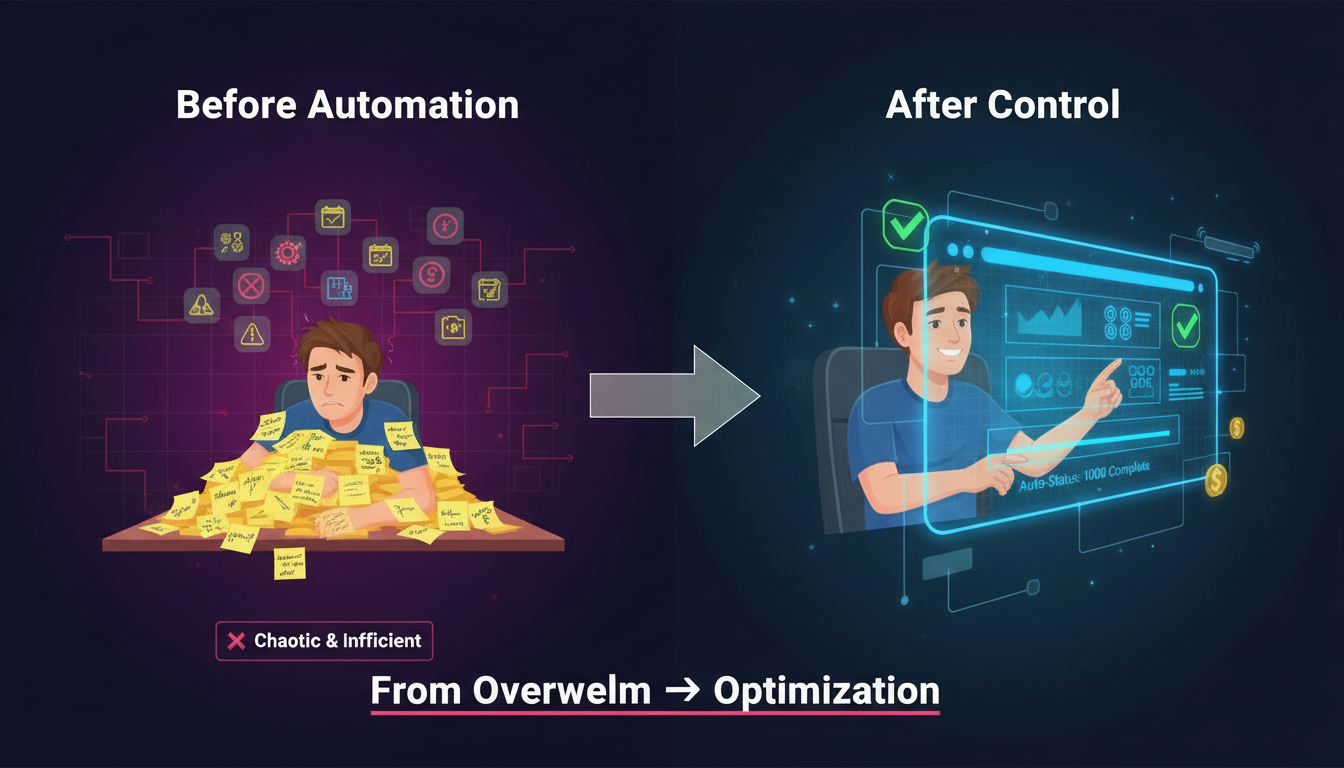

Most businesses don’t fail because of bad ideas.

They fail because their operations can’t keep up.

Leads come in late, follow-ups are missed, reports stay manual, and teams spend hours on repetitive work that should already be running in the background. This isn’t a people problem — it’s a workflow problem. And when automation is done right, it’s one of the fastest ways to restore control.

Yet despite its promise, many automation efforts quietly fail.

Not because automation doesn’t work — but because it’s approached the wrong way.

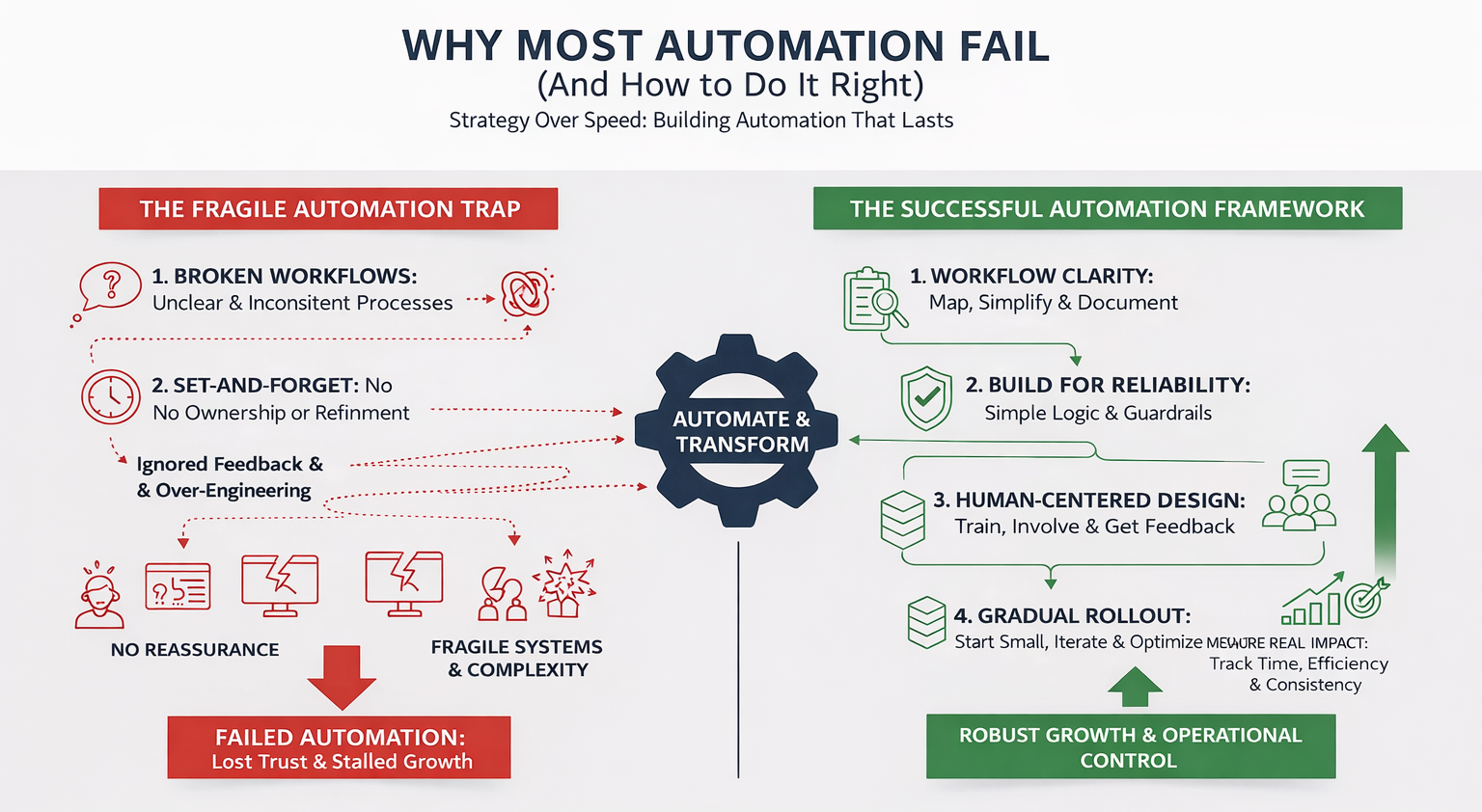

Automation Fails When Strategy Is Missing

Automation is often treated as a technical project. In reality, it’s an operational decision.

When businesses jump straight into automation without understanding how work actually flows, the result is fragile systems that break under pressure. Instead of improving operational efficiency, they introduce confusion.

Successful business process automation always starts with clarity, not tools.

Mistake #1 — Automating Without Fixing the Workflow

Broken Processes Don’t Improve With Automation

One of the most common reasons automations fail is simple:

the underlying process was never designed properly.

If a workflow is:

- Unclear

- Full of exceptions

- Dependent on individual judgment

Automation will only make those problems faster.

Before you automate internal processes, the workflow itself needs to be stable, repeatable, and documented.

Mistake #2 — Treating Automation as a One-Time Setup

Automation Is a System, Not a Switch

Many businesses assume automation is something you “set and forget.” That mindset almost guarantees failure.

In reality:

- Processes evolve

- Volumes increase

- Edge cases appear

Automation requires ownership, review, and improvement. Without that, systems slowly drift out of alignment with real operations.

This is where experienced workflow automation services focus differently — on long-term reliability, not quick wins.

Mistake #3 — Ignoring the Human Layer

Automation Without Alignment Creates Resistance

Automation doesn’t replace people — it removes waste.

But teams don’t always see it that way at first.

Failures happen when:

- Automation is imposed without explanation

- Teams aren’t trained on new workflows

- Feedback is ignored

When people understand why automation exists and how it reduces manual work, adoption improves dramatically.

Automation works best when humans and systems are designed together.

Mistake #4 — Trying to Automate Everything at Once

Over-Automation Leads to Fragility

Ambitious automation projects often collapse under their own weight.

Trying to automate too many processes at the same time can cause:

- Complex dependencies

- Hard-to-debug failures

- No clear success metrics

The smartest automation consultant will always recommend starting small — with workflows that are repetitive, predictable, and high-impact.

Momentum matters more than scale in the early stages.

Mistake #5 — No Measurement of Real Impact

If You Can’t Measure It, You Can’t Improve It

Automation fails quietly when success is never defined.

Effective automation tracks:

- Time saved

- Errors reduced

- Process consistency

- Operational visibility

Without metrics, businesses can’t tell whether automation is helping or just adding complexity.

Reliable automation supports decision-making — it doesn’t obscure it.

What Successful Automation Actually Looks Like

Automation that works shares a few consistent traits:

- Clear workflows before automation begins

- Simple logic instead of over-engineering

- Defined ownership and accountability

- Gradual rollout with feedback loops

- Focus on operational efficiency, not speed alone

This approach allows businesses to scale operations without increasing chaos.

Why Failed Automation Is More Dangerous Than No Automation

When automation fails, businesses often:

- Lose trust in systems

- Avoid future optimization

- Stay stuck with manual work

The real cost isn’t the failed automation — it’s the opportunity cost of staying inefficient.

Modern system integration, done thoughtfully, removes friction and creates stability across operations.

How to Do Automation the Right Way

To build automation that lasts:

- Understand the workflow before changing it

- Reduce unnecessary steps first

- Automate for reliability, not shortcuts

- Involve teams early

- Review and refine regularly

Automation should make operations boring — predictable, consistent, and under control.

That’s how real growth happens.

Conclusion

Manual operations may seem harmless, but they quietly hold back business growth by wasting time, increasing errors, and limiting scalability. Automation is no longer optional—it’s essential for businesses aiming to thrive in a competitive market.